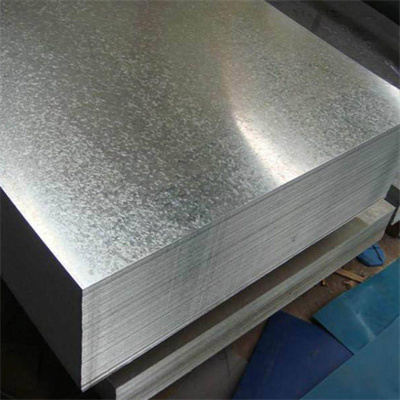

Hot Dip Galvanized Sheet

Classification :

Keywords: Steel Plate

PRODUCT DETAILS

Hot Dip Galvanized Sheet Description

Hot dip galvanizing is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot-dip galvanizing has the advantages of uniform coating, strong adhesion and long service life.

Hot-dip galvanizing is one of the effective means to delay the environmental corrosion of iron and steel materials, it is the surface of the cleaned, activated iron and steel products immersed in molten zinc, through the reaction and diffusion between iron and zinc, in the iron and steel products surface plating good adhesion of zinc alloy coating. Compared with other metal protection methods, the hot-dip galvanizing process has advantages in the protection characteristics of the combination of physical barrier and electrochemical protection of the coating, the bonding strength of the coating and the substrate, the compactness, durability, maintenance-free and economy of the coating, and its adaptability to the shape and size of the product. At present, hot-dip galvanized products mainly include steel plates, steel strips, steel wires, steel pipes, etc., of which hot-dip galvanized steel plates account for a large proportion.

The production process of hot galvanizing is as follows:

Mother material → degreasing → water washing → pickling → water washing → rinsing → flux solution → drying → hot galvanizing → cooling → inspection → packaging

Scope of Application

For a long time, hot-dip galvanizing process has been favored by people because of its low plating cost, excellent protection characteristics and beautiful appearance. It is widely used in automobile, construction, household appliances, chemical industry, machinery, petroleum, metallurgy, light industry, transportation, electric power, aviation and marine engineering and other fields.

Product Parameters

|

Product Name |

Hot Dip Galvanized Sheet |

|

Thickness |

0.12mm-6.00mm |

|

Width |

600mm-1500mm |

|

Length |

1m-12m, Support Customization |

|

Standard |

AISI, ASTM, DIN, JIS, GB, JIS, SUS, EN, etc. |

|

Zinc Layer |

Hot Galvanizing: 60-275g/m² |

|

Pre-galvanized: 80-275g/m² |

Chemical Composition

|

Standard |

Grade |

C |

Si |

Mn |

P |

S |

Ti |

|

Forcold Forming Chinese Standard |

DX51D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

DX52D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX53D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX54D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX56D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

DX57D+Z |

0.12 |

0.50 |

0.60 |

0.100 |

0.045 |

0.30 |

|

|

Forcold Forming Japanese Standard |

SGCC |

0.15 |

0.50 |

0.80 |

0.050 |

0.030 |

0.025 |

|

SGCD1 |

0.12 |

0.50 |

0.60 |

0.040 |

0.030 |

0.025 |

|

|

SGCD3 |

0.08 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

SGCD4 |

0.06 |

0.50 |

0.45 |

0.030 |

0.030 |

0.025 |

|

|

For Structure Japanese Standard |

SGC340 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.025 |

|

SGC400 |

0.25 |

0.50 |

1.70 |

0.200 |

0.035 |

0.150 |

|

|

SGC490 |

0.30 |

0.50 |

2.00 |

0.200 |

0.035 |

0.025 |

|

|

SGC510 |

0.30 |

0.50 |

2.50 |

0.200 |

0.035 |

0.025 |

|

|

For Structure AISI Standard |

S220GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

S250GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S280GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S320GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.025 |

|

|

S350GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

|

|

S550GD+Z |

0.20 |

0.60 |

0.70 |

0.100 |

0.045 |

0.150 |

Mechanical Properties

|

Grade |

Yield Strength MPa≥ |

Tensile Strength MPa≥ |

Elongation A%≥ |

|

DX51D Z/ZM/AZ/AM |

240-380 |

270-500 |

22 |

|

DX52D Z/ZM/AZ/AM |

140-300 |

270-420 |

26 |

|

DX53D Z/ZM/AZ/AM |

140-260 |

270-380 |

30 |

|

DX54D Z/ZM/AZ/AM |

120-220 |

260-350 |

36 |

|

S220GD Z/ZM/AM |

220 |

300 |

20 |

|

S250GD Z/ZM/AZ/AM |

250 |

330 |

19 |

|

S280GD Z/ZM/AM |

280 |

360 |

18 |

|

S300GD A/AM |

300 |

380 |

18 |

|

S320GD Z/ZM/AM |

320 |

390 |

17 |

|

S350GD Z/ZM/AZ/AM |

350 |

420 |

16 |

|

S450GD A/AM |

450 |

480 |

15 |

|

S550GD Z/ZM/AZ/AM |

550 |

550 |

- |

Galvanized Surface Selection

|

Zero Spangle |

Minimized Spangle |

Normal Spangle |

Large Spangle |

|

|

|

|

|

|

Use of The Environment |

Recommended Zinc Thickness |

|

Indoor Use |

Z10 or Z12 (100g/㎡or 120g/㎡) |

|

Suburbs |

Z20 and Painting (200g/㎡) |

|

Urban or Industrial Area |

Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Coastal Area |

Thicker than Z27 (270g/㎡) or G90 (US Standard) and painted |

|

Punch or Deep Drawing Application |

Thicker than Z27 (270grams/㎡) or G90 (US Standard) avoid coating peeling after stamping |

|

Surface Treatment Type |

Code |

Features |

|

Chromic Acid Treatment |

C |

Good corrosion resistance, suitable for bare state |

|

Chromic Acid Treatment+Oiling |

S |

Good corrosion resistance |

|

Phosphoric Acid Treatment (Including Sealing Treatment) |

P |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Including Sealing Treatment)+Oiling |

Q |

Has a certain corrosion resistance, good paint performance, prevent rust during transportation and storage |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment) |

T |

Have a certain corrosion resistance, good paint performance |

|

Phosphoric Acid Treatment (Excluding Sealing Treatment)+Oiling |

V |

Has a certain corrosion resistance, good paint performance, and prevent rust |

|

Oiling |

O |

Prevent rust during transportation and storage |

|

No Treatment |

M |

Suitable for immediate painting |

Material Comparison

|

Chinese Standard |

Japan Standard |

European Standard |

|

DX51D Z/DC51D Z (CR) |

SGCC |

DX51D Z |

|

DX52D Z/DC52D Z |

SGCD1 |

DX52D With |

|

DX53D Z/DC53D Z/DX54D Z/DC54D Z |

SGCD2/SGCD3 |

DX53D Z/DX54D Z |

|

S220/250/280/320/350/550GD Z |

SGC340/400/440/490/570 |

S220/250/280/320/350GD Z |

|

DX51D Z/DD51D Z (HR) |

SGHC |

DX51D Z |

Warehouse Storage

Hebei Yehui Metal Materials Co., Ltd. as a leader manufacturer in steel supplier from China, is a reliable and integrity steel supplier. With more than 10 years steel processing and exporter experiences, we have a factory building of 20000 square meters and annual production of 23,000 tons. We specialized in the production of stainless steel, carbon steel, galvanized steel, aluminum, copper products, etc., suitable for fields such as engineering, coal mining, textiles, electricity, boilers, machinery, etc. Our products have passed the ISO9001 quality system certification and the EU CE certification.

Packing And Shipping

We use professional and environmentally friendly packaging materials and customize the packaging according to the characteristics of the goods to ensure that the goods are safe and intact during transportation. At the same time, we have an efficient delivery process and a complete logistics system to ensure that you receive the goods as soon as possible.

Customer Feedback

Please feel free to leave us message if you have any question about us and our products.

Application Field

We mainly produce galvanized steel, color-coated steel, stainless steel, carbon steel, aluminum and other steel products. These steels have stable performance and reliable quality. They are suitable for engineering, coal mining, textiles, electricity, boilers, machinery and other industries, and can meet the actual needs of different customers. Friends from all walks of life are welcome to consult and cooperate!

COOPERATIVE PARTNER

FAQ

FAQ

Q1: Are You Manufacture or Trade Company?

A1: We are the professional manufacturer of stainless/carbon/galvanized steel products located in China. Welcome to contact us and visit our factory before you place orders.

FAQ

Q2: Can I get free samples?

A2: Of course you can. We can produce according to your samples or technical drawings. Contact us by whatsapp or email to get free samples and you will get the sample after 3-7 working days.

FAQ

Q3: How do you guarantee the quality?

A3: We can send free samples to you, we can accept third-party testing. We also have test certificate, every batch goods will be testing before shipment, and the testing report will delivery to you with your goods.

FAQ

Q4:How many coutries you already exported ?

A4: Exported to more than 50 countries mainly from Qatar, America, Russia, Belarus, Saudi Arabia, United Arab Emirates, Kuwait, Brazil, Egypt, Turkey, Jordan, India, etc.

FAQ

Q5:How long is your delivery time?

A5:Within 5 days for stock size, 7-15 working days for customized size.

FAQ

Q6: Can you OEM or ODM?

A6: Yes, we have a strong developing team. The products can be made according to your request

FAQ

Q7: What is the MOQ?

A7: If you are scheduling to place a small quantity order or trial order, feel free to contact us, we can meet your requirements.

FAQ

Q8:What are the certifications for your products?

A8:We have ISO 9001, MTC, third parties' inspections are all available such SGS, BV ect.

RELATED PRODUCTS

GET A FREE QUOTE